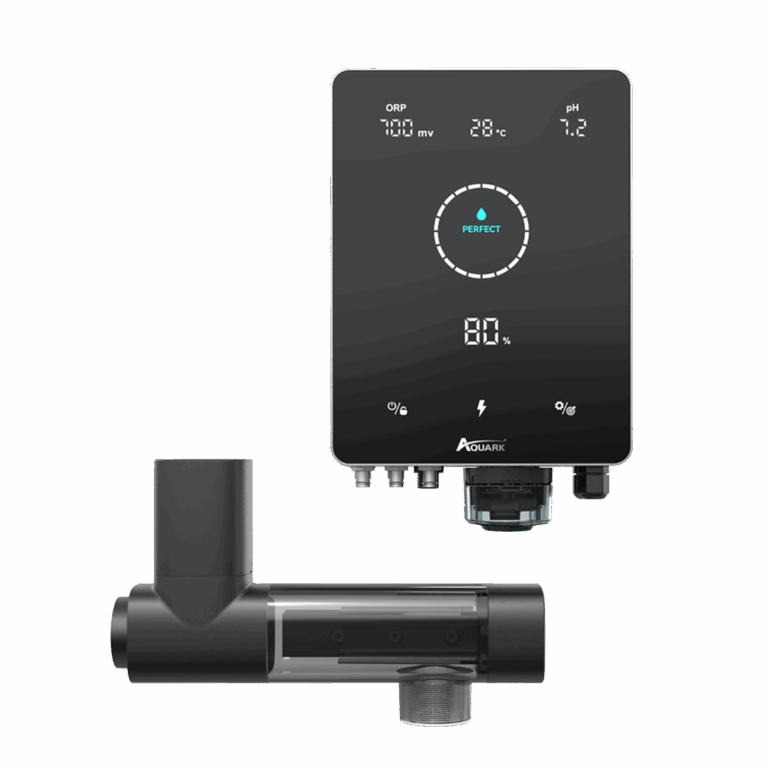

Full inverter Chlorinator with InverTurbo technology

InverTurbo technology adopts an advanced PID* algorithm for accurate control of chlorine production and pH regulation.

With self-adaptation to different situations and 130% powerful Turbo, InverTurbo saves more time whether during initial disinfection or after having a party.

It can also operate at a low salt level of 1g/L and keep crystal pure water without worries about additional salt maintenance for up to 180 days.

* The PID controller is a device that receives input data from sensors, calculates the difference between the actual value and the desired setpoint, and adjusts the outputs to control variables such as temperature, flow rate, speed, pressure, and voltage. It does this through three mechanisms: i. Proportional control, which reacts to the current error; ii. Integral control, which addresses accumulated past errors; and iii. Derivative control, which predicts future errors. The PID controller sums these three components to compute the output. This architecture allows PID controllers to effectively maintain process control and system stability.

- 75mm slimmest thickness.

- Innovative self-cleaning cell.

- Salt level detection.

- Replaceable electrode.

- Recirculation pump control.

- Built-in pH regulator with automatic and manual modes.

You may also be interested in…

Aquablue salt chlorination system